Lindemann Silikon GmbH & Co.KG

Extrusion of silicone products

The Specialist in silicone

CALL NOWSilicone injection molding (LIM – Liquid Injection Molding) is one of the most modern and efficient methods for manufacturing silicone components. This process enables the production of precise, durable, and highly resistant parts, making it indispensable in many industries, including the automotive industry, medical technology, electronics, and household goods.

How Does the Injection Molding Process Work?

In injection molding, liquid silicone (LSR – Liquid Silicone Rubber) is injected into a mold under high pressure. This is followed by vulcanization, which gives the material its excellent mechanical properties and temperature resistance. The entire process is fully automated, enabling large-scale production with the highest precision.

Advantages of Injection Molding Technology

-

High precision and repeatability – Each part has identical specifications, which is crucial for applications requiring tight tolerances.

-

Resistance to extreme conditions – Silicone withstands temperatures ranging from -60°C to +250°C.

-

Safety and biocompatibility – Silicone components can be used in medical technology and in food contact applications.

-

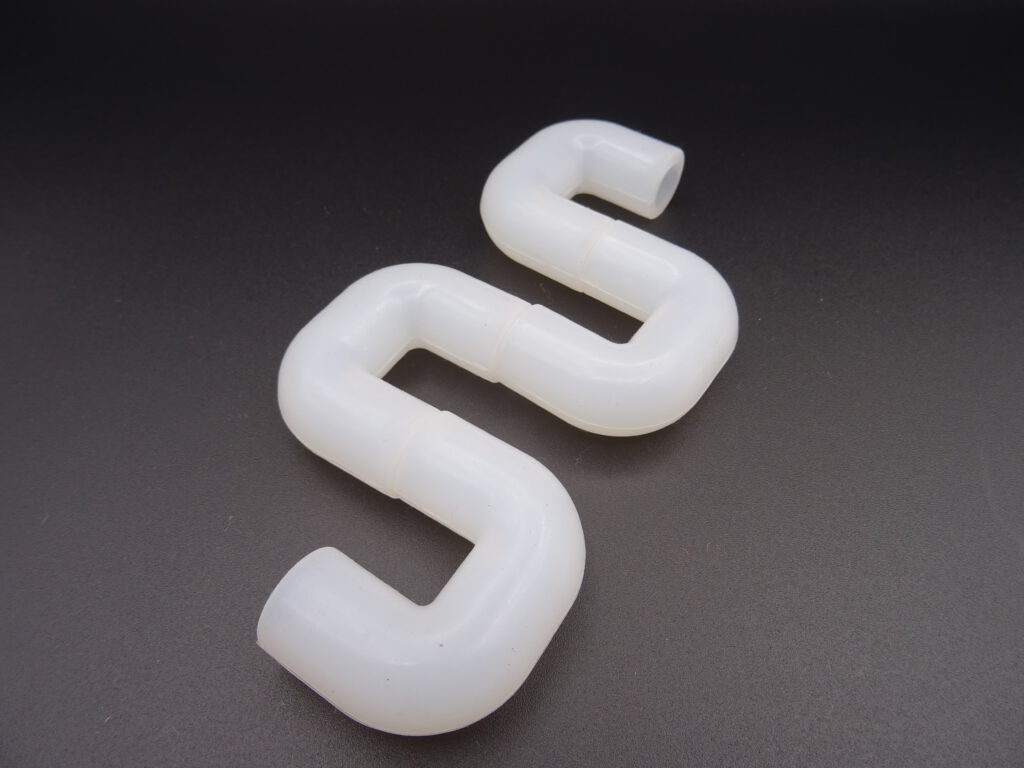

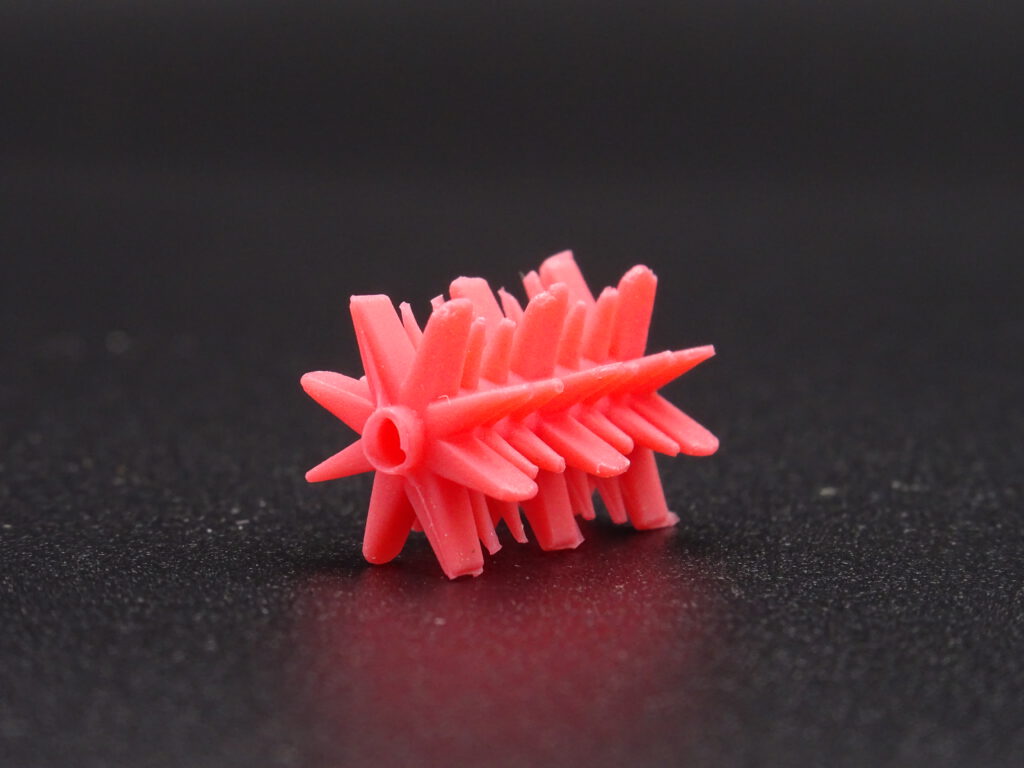

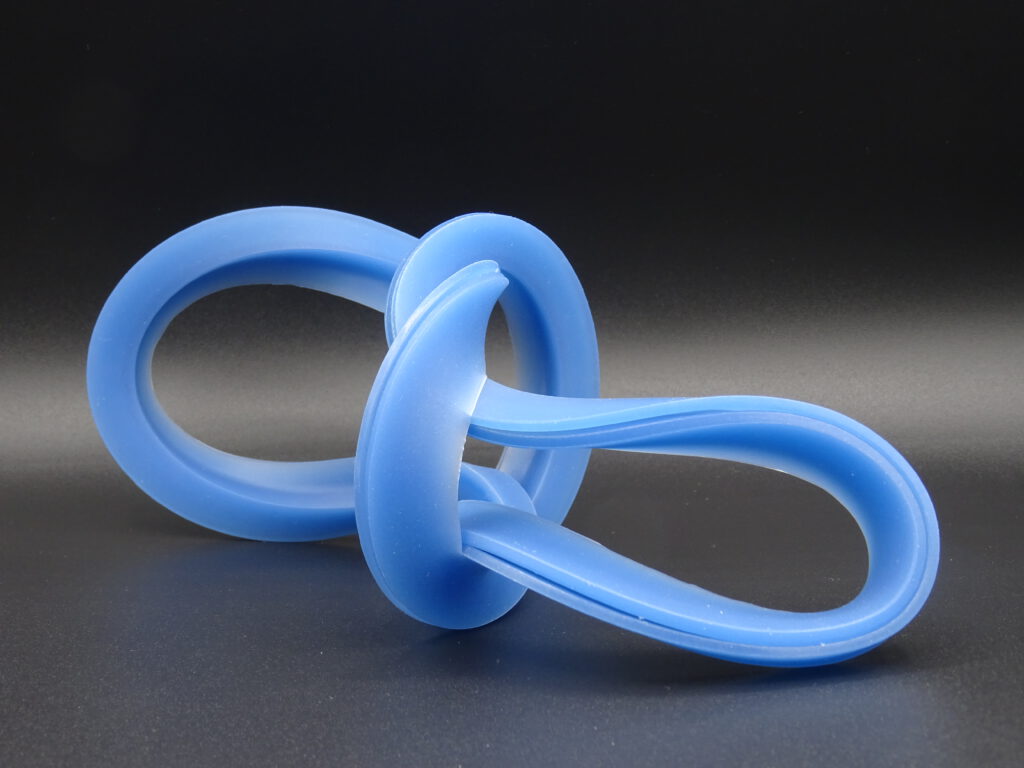

Ability to produce complex geometries – This process enables the creation of parts with irregular shapes, thin walls, and intricate structures.

-

Fast production cycles – The fully automated process minimizes production time and material waste.

-

High material efficiency – Precise dosing of silicone results in minimal production waste, improving manufacturing cost-effectiveness.

Applications of Silicone Injection Molding

-

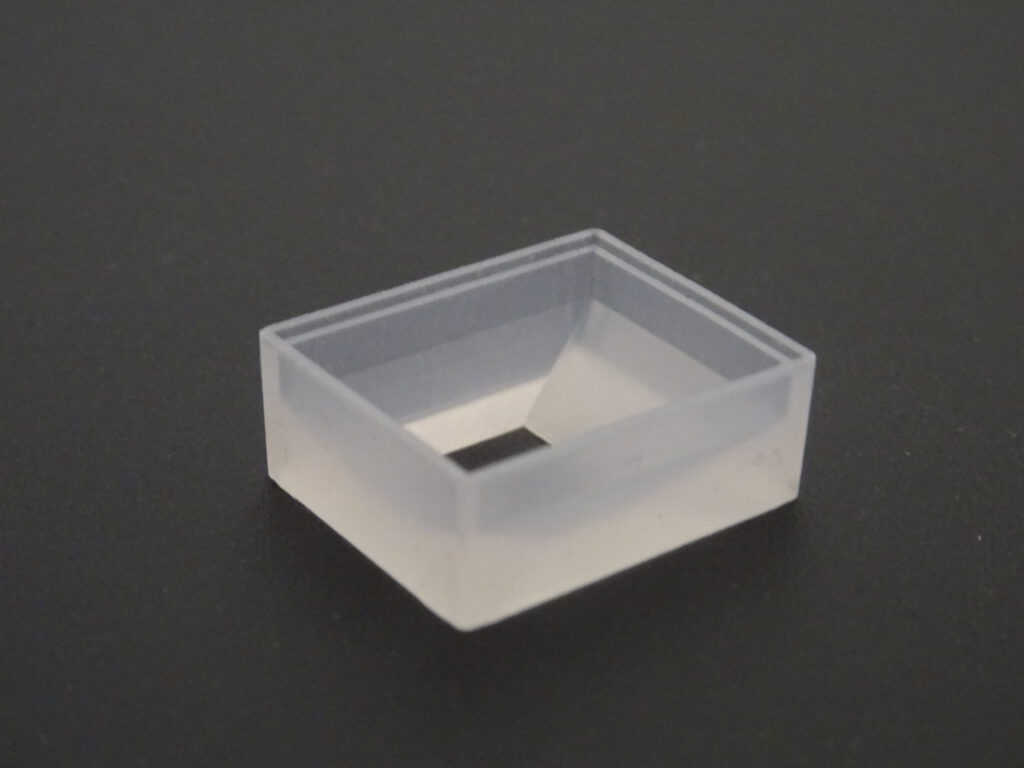

Medical technology: Seals for medical devices, oxygen masks, implant components, catheters, and other applications where biocompatibility is essential.

-

Automotive industry: Temperature- and chemical-resistant components, seals, hoses, cable grommets, and vibration-damping elements (learn more).

-

Household goods and electronics: Keyboard membranes, cable protection, insulating components, heat-resistant baking molds, and flexible kitchen tools (more details).

-

Industry and mechanical engineering: Precision seals, elastic couplings, vibration-damping elements, and custom-molded parts for specialized applications (learn more).

Injection Molding at Lindemann

Lindemann specializes in the production of silicone components using injection molding. With modern machinery and advanced technology, we deliver high-quality products tailored to our customers’ specific needs. We support our partners from design to serial production, ensuring the highest precision, durability, and compliance with international standards.

Our company continuously invests in new technologies and optimizes production processes to ensure maximum efficiency. Our expertise in injection molding allows us to develop innovative solutions and successfully implement even complex projects.

In addition to injection molding with LSR, we also offer comprehensive solutions for various types of silicone such as HTV and RTV in other manufacturing processes (more information here). Furthermore, we manufacture custom-made silicone molded parts for a wide range of applications.

For your specific silicone injection molding requirements, our experienced team is ready to provide expert support. We take pride in offering customized solutions that combine the highest precision, efficiency, and quality. Our commitment extends throughout the entire process – from initial concept development and tool design to serial production. Contact us today to learn how our advanced injection molding technologies can optimally advance your project.

Leave us a message, and we will get in touch with you!

Mit dem Laden der Karte akzeptieren Sie die Datenschutzerklärung von Google.

Mehr erfahren