Lindemann Silikon GmbH & Co.KG

High-quality silicone molded parts made from HTV or LSR silicone

Your Specialist in silicone

Contact nowCustomized silicone molded parts

Our competence - silicone molded parts made of HTV and LSR

As a company, we have also been manufacturing silicone molded parts for more than twenty years.

Our range of services covers the entire value-added process of a silicone molded part: from design consulting, tooling, prototyping, sampling phase to series production.

The interesting properties of the material enable the production of parts for a wide range of applications in the fields of industry and medicine.

HTV Silicone and Liquid Silicone (LSR)

We offer HTV silicone and liquid silicone rubber (LSR) molded parts. HTV is the abbreviation for High Temperature Crosslinked and LSR is the abbreviation for Liquid Silicone Rubber.

HTV silicone is used wherever high drinking water quality is required or where food approvals are linked to the products. Liquid silicone (LSR) is ideal when high mechanical properties are required in addition to high food quality. One important example of this is tear resistance.

In addition, more complex molded parts are usually made from liquid silicone (LSR).

Each silicone molded part is as individual as the customer

Our employees attach great importance to finding the right silicone molded part or parts for each customer. For this reason, we take a lot of time to find out together with the customer what is important in the specific case. Important points are the geometry, the cross-section, the hardness and the color of a silicone molded part.

Furthermore, we produce foam profiles for various applications in medical technology. We accompany the entire process from design consulting and tooling to prototyping and sampling of the molded silicone parts. There is a wide range of dimensions – from small sizes to series production.

Silicone molded part - important properties

Regardless of the size, shape and finish, all parts are considered to be very resilient. The hardness can range from 30 to 90 Shore. A particular advantage of silicone is its high temperature tolerance. Our products can be used in ranges between -60 degrees Celsius and 280 degrees Celsius. In addition, neither UV rays, nor rain, wind or other weather conditions can harm molded parts made of silicone.

Application of silicone molded parts - food and medical technology

Silicone molded parts find numerous applications, especially in the food industry and in medical technology. They are used to seal devices, equipment and special interfaces. They can also be used to seal cameras or lamps. Furthermore, they are used for acoustic damping, insulation and protection of sensitive areas in medical technology.

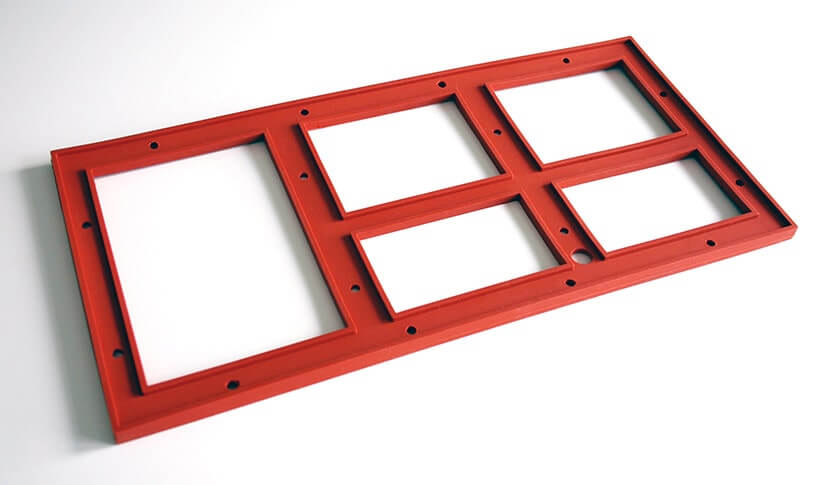

Assembly and production of sealing frames

In the field of confectioning fall:

- the gluing, cutting and printing,

- cutting and cutting to length,

- the punching and gluing as well as

- the printing of extrudates.

Furthermore, according to customer requirements, we can:

- produce sealing frames,

- produce self-adhesive profiles,

- perform packaging and labeling and

- procure or integrate additional components.

- Creation of technical drawings for a molded part

- Production of small series

- Production of prototypes

- HTV solid silicone rubber molded parts and LSR liquid silicone rubber molded parts

- Customer-specific solutions

- 20 years of experience in silicone molded parts construction

- Planning and consulting in design

- In Shore hardness from 30 to 90 Shore

- Specialties: Surface treatment (Smooth Surface) With printing, tight manufacturing tolerances

Are you interested in our products or a question? Then contact us now.