Lindemann Silikon GmbH & Co.KG

Silicone moulded hose

Your Specialist in silicone

Contact nowSilicone Wrapped Hoses from Lindemann Silikon

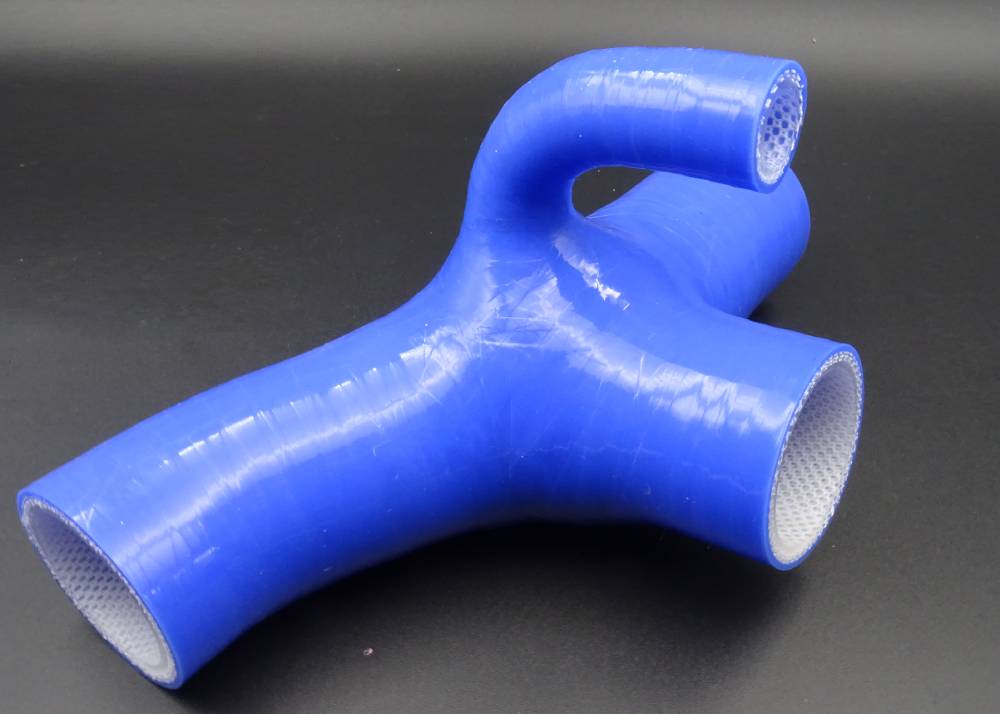

Wrapped Silicone Hoses are indispensable in the automotive industry, particularly for cooling and heating systems. They provide a tailored solution precisely aligned with specific needs and requirements. Thanks to Lindemann Silicone GmbH’s expertise in silicone material processing, these hoses guarantee durability and reliability under extreme conditions. From design to production, our company oversees the entire process to deliver high-quality wrapped silicone hoses that meet exact specifications.

What are silicone-wrapped hoses?

Imagine a task that requires a flexible approach, something that can twist and turn effortlessly. This is where silicone-wrapped hoses come into play. They are not just simple hoses but true specialists in the world of tubing. Their production begins with wrapping silicone sheets around a metallic tool, which gives them their initial shape. They are then reinforced with a special tape, providing them with their distinctive wrapped structure. This process makes the wrapped hoses highly adaptable and ready for a variety of applications. Thanks to this specific manufacturing method, they can also be customized to different diameters and lengths, making them an ideal solution for numerous technical challenges.

Wrapped Hoses: Versatile Applications

Silicone Wrapped Hoses are widely used in the automotive industry, primarily due to their excellent heat resistance and flexibility. They are typically employed in cooling and heating systems, turbochargers, intercoolers, as well as for water supply, oil, and fuel delivery. Their ability to withstand extreme temperatures and pressure conditions makes them the ideal choice for critical applications where conventional rubber hoses might fail.

How are wrapped hoses manufactured?

The manufacturing process of wrapped hoses follows these revised steps:

- Design and Tool Preparation: The hose design is developed, considering specifications such as diameter, length, wall thickness, and shape. Subsequently, metallic tools and molds are prepared for the wrapping process.

- Determination of Layer Count and Reinforcement Material: At this stage, the number of material layers to be applied and the type of reinforcement fabric used to strengthen the hose structure are determined, which are crucial for its strength and flexibility.

- Wrapping: Silicone sheets are wrapped around a metallic tool to form a spiral structure.

- Vulcanization: The wrapped material undergoes a vulcanization process, a curing method using high temperatures. This process gives the hoses their final properties, such as mechanical and thermal strength.

- Finishing: After vulcanization, the hoses are cut to the required length and prepared for quality inspection.

- Quality Control: Each hose is meticulously inspected to ensure it meets all required technical standards and quality criteria. This includes tests for leak tightness, pressure resistance, thermal, and chemical durability.

This production process ensures that wrapped hoses are not only of high quality but also tailored to meet the specific demands of the applications in which they are intended to be used.

Silicone - A Versatile and Durable Material

At Lindemann, we rely on silicone as a robust and versatile material.

Thanks to its unique properties, silicone is perfectly suited for use in various industries and applications. Silicone stands out for being:

- Flexible at low temperatures down to -60°C (and up to -100°C with special formulations)

- Taste- and odor-neutral

- Sterilizable

- Weather-resistant

- Aging-resistant

- Highly insulating and non-conductive

By manufacturing our molded silicone hoses, we offer you a product that is not only tailored to your specific needs but also robust and durable. Whether you operate in the automotive industry or medical technology, we provide molded hoses that are perfectly suited to you and your industry. To ensure this, our silicone blends are also available with various certifications.

- Very wide range of dimensions up to 50mm

- Wide range of textile braids

- Platinum fabric hoses

Are you interested in our products or have a question? Feel free to contact us now.

Your Manufacturer for Molded Hoses

We aim to offer you products that meet your expectations and applications. That’s why we provide not only molded hoses but also additional products like silicone hoses, silicone profiles, and silicone foams. If you have any questions about our molded hoses or other products, feel free to contact us.