Lindemann Silikon GmbH & Co.KG

Silicone foam products

Your Specialist in silicone

Contact nowSilicone Foam: Versatile Material for Thermal Insulation and Industrial Applications

Silicone foam is a composite material produced from silicone with the addition of blowing agents. The blowing agents cause the silicone base mixture to expand and create silicone foam. This results in a closed-cell material with unique properties. Closed-cell means that there is no connection between individual cells, preventing moisture from penetrating the cell structure.

This foam finds diverse applications in various industrial sectors and other industries. It is used as a sealant or insulation material, as well as in the form of foam hoses, foam profiles, foam molded parts, and round cords. Its various positive properties make it a sought-after material in industries such as automotive manufacturing, shipbuilding, and even aviation.

Properties of silicone foam

Silicone foam is a versatile and highly adaptable material used in numerous industries. In this article, we will take a closer look at the unique properties of silicone foam, especially its ability for thermal insulation, and explore four main product groups derived from it: hoses, profiles, molded parts, and sheets.

The various positive attributes of silicone foam make it an outstanding choice for insulation or sealing applications. Silicone foam exhibits high temperature resistance, is food-safe, hypoallergenic, and fungicidal. As a result, this material is suitable for a wide range of industries, including the food and pharmaceutical sectors, as well as medical technology.

Furthermore, silicone foam:

- is non-corrosive.

- is non-conductive

- easily deformable

- resistant to weather, moisture, and UV

- elastic

- thermal insulating

Lindemann Silicone Foam Hoses for Flexible Applications

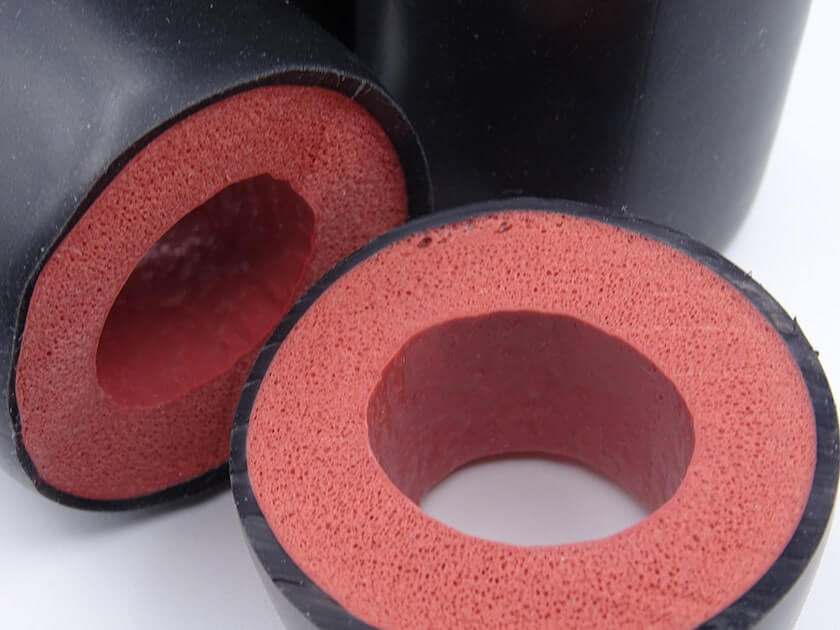

Our closed-cell silicone rubber foam hose not only provides insulation and insulation properties but also offers the following advantages as seals:

- Lower density

- Higher compression tolerance

- better recovery behavior after deformation

Silicone foam hoses combine flexibility with exceptional temperature resistance, making them a preferred material in the automotive industry, mechanical engineering, and aerospace. Their adaptability to various sizes and shapes makes them ideal for specialized requirements.

We dose the specific blowing agents differently depending on the desired foam type. We are happy to assist you in selecting the appropriate solution according to your needs, including products with protective outer layers.

For more information, please refer to the Silicone Foam Hoses section below.

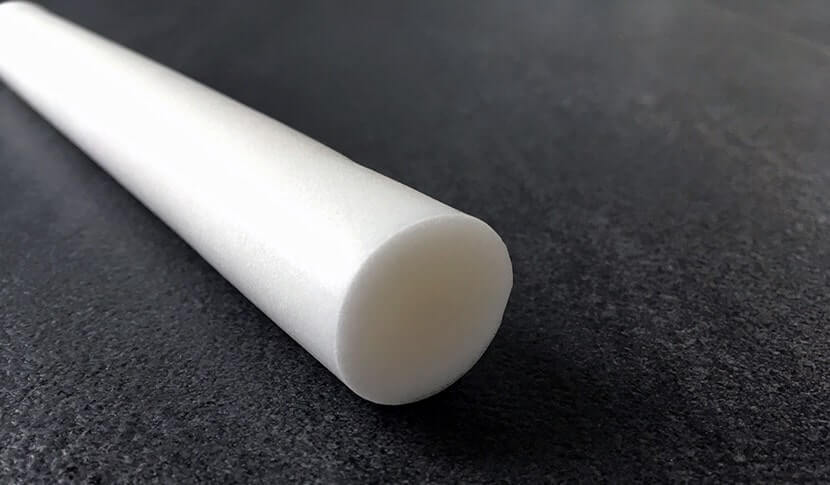

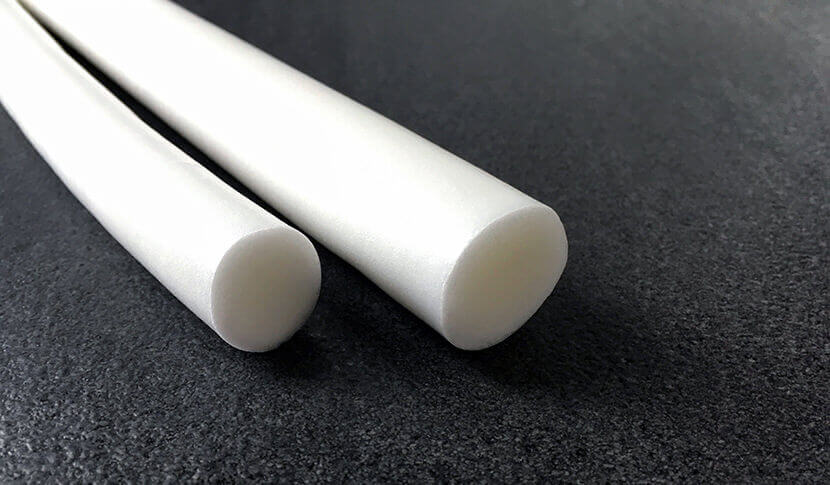

Lindemann Silicone Foam Profiles and Foam Round Cords

Silicone foam profiles are unique and versatile products that can be manufactured in a variety of shapes and sizes to suit a wide range of applications. Our offerings encompass both simple shapes like square profiles and complex geometries that can be custom-made to meet your specific needs and preferences.

These profiles are produced using state-of-the-art extrusion technology, allowing us to create silicone foam profiles suitable for a multitude of applications. They are ideal as seals and insulators in windows, doors, and electronic enclosures. An essential advantage of silicone foam profiles is their high temperature resistance, making them indispensable materials in environments where temperature control is crucial.

In addition to these profiles, we also offer foam round cords available in various configurations. These round cords complement our product range and provide additional customization options for specific requirements.

With our diverse range of silicone foam products, you have access to robust, durable, and adaptable solutions for a wide range of applications. Whether you require simple or complex designs, we have the expertise and technology to meet your requirements.

If you are looking for solid silicone profiles, please check this page: Silicone Profiles.

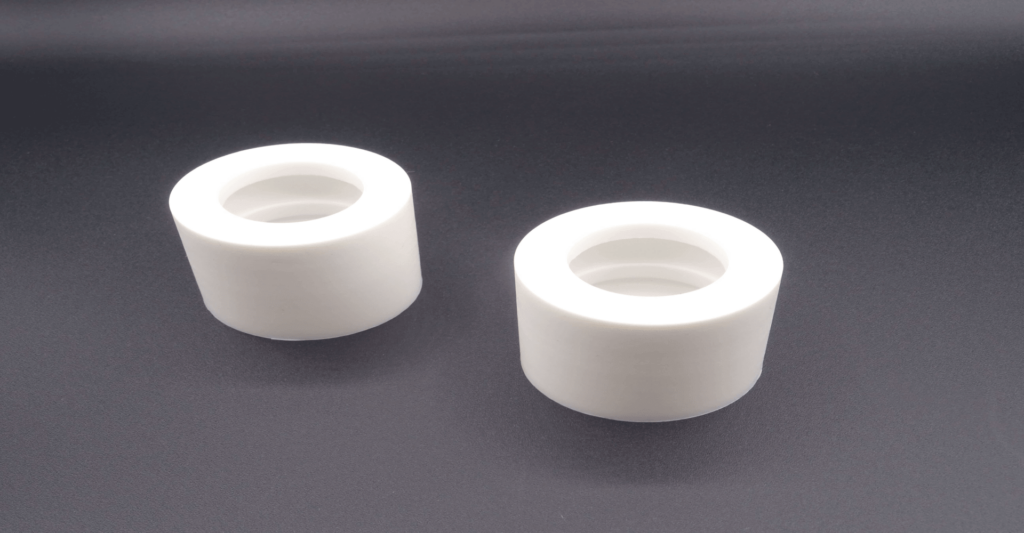

Customized Molded Parts Made of Silicone Foam

These custom foam molded parts find wide application in medical technology, electronics, and automotive industries, offering tailored solutions for complex shapes. They meet specific requirements such as shock absorption and thermal insulation. The manufacturing of these parts is done through two main methods: casting and cutting.

In the casting process, the material is poured into specially designed molds to create precise and intricate parts. This method is particularly suitable for producing parts with very specific, detailed shapes, and textures.

In the cutting process, the material is shaped from larger silicone foam sheets. This can be achieved through various methods such as waterjet cutting, laser cutting, knife cutting, or punching. Each of these techniques has its own advantages and is chosen based on the required precision and material characteristics.

Types of Silicone Foam

Depending on the dosage of the blowing agent, various types of foam can be produced. Thus, you have the choice of:

hardness

density

5° to 30° Shore

0,25 to 0,65 g/cm3

material composition

For the production of our silicone foam, we differentiate between two blends that result in different physiological properties.

- Technical, NON-FDA Quality

- FDA Quality

Manufacturing of Silicone Foam

At our company, we place great importance on the customized manufacturing of silicone foam to perfectly meet our customers’ specific requirements. With our years of experience in the industry and the use of state-of-the-art machinery, we are capable of producing high-quality silicone foam products that are precisely tailored to our customers’ needs.

We utilize specially formulated silicone blends that allow us to produce silicone foam with varying densities and strengths to cover a wide range of industrial applications.

Our team of experienced professionals meticulously monitors the entire manufacturing process to ensure that each product meets our stringent quality standards and is optimized to meet the individual requirements of our customers.

Assembly or Finishing

Depending on your preferences, we strive to find the appropriate solution with you. Accordingly, we offer the option to bond profiles into rings or frames. Self-adhesive profiles can also be applied. Please feel free to contact us with any special requests or ideas.

Silicone foam meets extensive approval criteria and industry-specific standards.

To ensure that our silicone foam products are applicable to your industry, we can expand the base formulations to include various approvals.

For the food industry:

- BfR XV Silicone

- FDA § 177.2600

- EG VNr. 1935/2004

For the drinking water and sanitary sector:

- KTW A Cold and Hot Water

- DVGW W 270

- WRAS

- 3A Sanitary Standard

For the pharmaceutical sector:

- USP Class VI

- ISO 10993

- Foamed Hoses

- Foamed Profiles

If you have any questions about our silicone foam or other products, please don’t hesitate to contact us. We are always available by phone or through our contact form. Together, we will find a solution for all your needs.